A number of Oregon companies are using innovative techniques to turn raw timber or lumber into value-added engineered wood products. These products, also known as advanced wood products or simply “mass timber,” typically mean more mills, more jobs and more money staying in Oregon.

Examples of engineered wood products

Cross-laminated timber (CLT) is made by adhering dimension lumber into large panels several layers thick, with each layer’s wood fibers running perpendicular to the adjacent layers. Currently, the largest CLT panels produced in the world are about 65 feet long and 20 feet wide. CLT panels typically range in thickness from 5 to 16 inches and are used to build walls, floors and roofs. Panels can be prefabricated with cutouts for windows, plumbing, electrical wiring and ventilation, and assembled into large, multistory buildings that otherwise might be built from steel or concrete.

Glued-laminated timber (Glulam) is a stress-rated engineered wood product made of wood laminations, or “lams,” that are bonded together with strong, waterproof adhesives. Glulam is used in commercial and residential applications, ranging from simple garage door headers and floor beams to huge, dramatic, curving beams that are an architectural focal point.

Laminated veneer lumber (LVL) is the most widely used structural composite lumber product. It is produced by bonding thin wood veneers together into a large board called a billet. The LVL billet is then sawed to desired dimensions depending on the construction application. The many uses of LVL include headers and beams, rafters, rim board, scaffold planking, studs and flange material for prefabricated wood I-joists and truss components.

Mass plywood panel (MPP) is a veneer-based engineered wood product that is similar to plywood, but on a massive scale. Finished panels can be up to 12 feet wide, 48 feet long and 24 inches thick. The panels can be used as an alternative to CLT in similar applications, including constructing multistory buildings.

Nail-laminated timber (NLT) is created by nailing together dimension lumber stacked on edge into a single structural element. NLT is used in floors, decks and roofs, and elevator and stair shafts.

Parallel strand lumber (PSL), laminated strand lumber (LSL) and oriented strand lumber (OSL) are structural composite lumber products made from flakes of wood called strands that are combined with adhesive, pressed into a large mat and sawed into various sizes for use as studs, headers or beams.

Plywood is an engineered wood product made by gluing together thin sheets of wood veneer with the grains of adjacent layers alternating to create strong boards used for the construction of roofs, walls and floors.

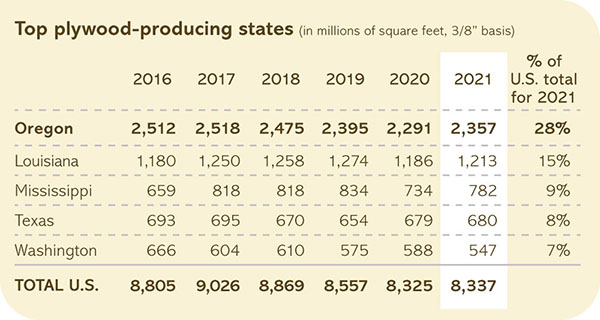

Oregon is the nation’s top plywood producer

Oregon dominates U.S. production of softwood construction plywood. In fact, Oregon accounted for about 28 percent of the total U.S. plywood production in 2019, up from 25 percent in 2010.

Overall, U.S. plywood production has been challenged by cheaper strand-board products that have taken market share in some construction uses. Oregon has no mills that make strand-board. Yet plywood is still a significant business that has rebounded from its recessionary low in 2009.

Oregon universities team up on engineered wood research

Researchers at major Oregon universities and elsewhere are conducting fire and seismic tests of cross-laminated timber and other engineered wood products that show these products are a safe, feasible alternative to concrete and steel for building mid-rise and even high-rise structures.

Oregon State University and the University of Oregon have jointly launched the TallWood Design Institute, a national education and research center focused on advancing innovative buildings and wooden structural components made in Oregon. It brings together expertise in forestry, architecture, wood science and engineering from both universities to position Oregon as the leader in emerging markets for new wood products, and as a national hub for expertise in innovative tall wood building design and advanced computer numeric control (CNC) manufacturing.

The TallWood Design Institute provides architectural design, structural testing, applied research, and delivers a technical education program across the state.

For more information, go to tallwoodinstitute.org.